The Silent Revolution: How Digital Twins Are Reshaping Software And Industry 4.0

“The Silent Revolution: How Digital Twins are Reshaping Software and Industry 4.0

The Silent Revolution: How Digital Twins are Reshaping Software and Industry 4.0

Imagine a world where you could predict the future, not through mystical prophecies, but through the meticulous replication of reality. This isn’t science fiction; it’s the power of digital twins. These virtual counterparts of physical assets, processes, or systems are quietly revolutionizing software development and driving the transformative power of Industry 4.0. They are the silent architects of a more efficient, resilient, and innovative future.

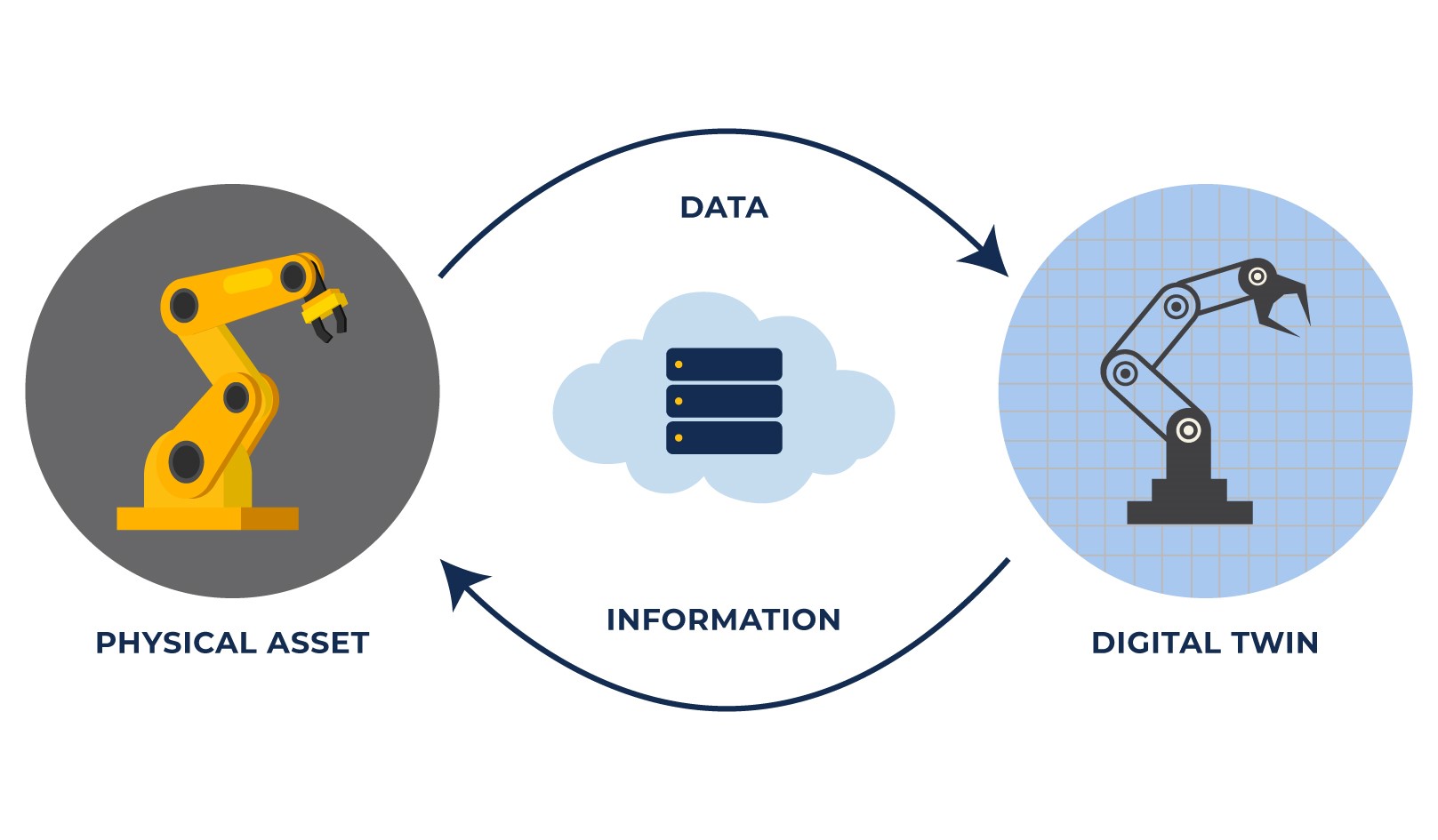

But what exactly is a digital twin? It’s more than just a 3D model; it’s a dynamic, living representation that continuously updates itself based on real-time data from its physical counterpart. Think of it as a sophisticated mirror reflecting the health, performance, and behavior of its physical twin. This constant feedback loop allows for unprecedented levels of insight and control, leading to a paradigm shift across various industries.

From Conception to Optimization: The Software Development Lifecycle Transformed

For years, software development has been a process fraught with challenges: unexpected bugs, delayed releases, and costly rework. Digital twins are changing this narrative. By creating a virtual replica of the software system, developers can test, analyze, and optimize the code in a safe, controlled environment. Imagine building a house virtually before laying a single brick – identifying potential structural flaws, optimizing the layout, and ensuring everything fits perfectly before investing time and resources in the physical construction. This is precisely the power digital twins bring to software development.

Consider a complex financial trading platform. A digital twin allows developers to simulate millions of transactions under various market conditions, identifying potential bottlenecks and vulnerabilities before they impact real-world operations. This proactive approach minimizes risk, accelerates development cycles, and significantly reduces the cost of errors.

The Factory Floor Transformed: Predictive Maintenance and Optimized Production

The impact of digital twins extends far beyond the software realm. In the manufacturing sector, they are revolutionizing Industry 4.0 by enabling predictive maintenance and optimized production processes. Imagine a factory floor where every machine has its own digital twin. These virtual representations constantly monitor the machine’s performance, identifying potential failures before they occur. This predictive capability minimizes downtime, reduces maintenance costs, and ensures consistent production output.

Let’s consider a scenario with a critical assembly line machine. Traditional maintenance relied on scheduled inspections, often leading to unexpected breakdowns and costly production delays. With a digital twin, sensors embedded in the machine feed data to its virtual counterpart, which analyzes the data to predict potential failures. This allows for proactive maintenance, preventing costly disruptions and maximizing operational efficiency. The emotional relief felt by factory managers, spared from the stress of unexpected shutdowns, is immeasurable.

Beyond the Machine: Simulating Entire Production Lines and Supply Chains

The power of digital twins doesn’t stop at individual machines. They can be used to simulate entire production lines, supply chains, and even entire factories. This allows manufacturers to optimize their operations, identify bottlenecks, and improve overall efficiency. Think of it as a virtual sandbox where manufacturers can experiment with different scenarios, testing the impact of changes before implementing them in the real world.

For example, a car manufacturer can use a digital twin of its assembly line to simulate the impact of introducing a new robot or changing the layout of the factory floor. This allows them to identify potential problems and optimize the process before making any costly physical changes. The potential cost savings and increased efficiency are staggering.

Design and Engineering: A Virtual Playground for Innovation

Digital twins are not just for monitoring and optimization; they are also powerful tools for design and engineering. By creating a virtual representation of a product, engineers can test and refine their designs before investing in costly prototypes. This iterative process accelerates innovation and allows for the creation of more robust and efficient products.

Imagine designing a new aircraft. Instead of building multiple expensive prototypes, engineers can use a digital twin to simulate the aircraft’s performance under various flight conditions. This allows them to identify and address design flaws early in the process, saving time and resources. The feeling of confidence and control this provides is invaluable.

Data-Driven Decisions: Unlocking the Power of Real-Time Insights

The core of a digital twin’s power lies in its ability to process and analyze vast amounts of real-time data. This data-driven approach allows for more informed decision-making across all levels of an organization. From identifying minor inefficiencies to predicting major disruptions, digital twins provide a level of insight previously unimaginable.

Consider a smart city implementing a digital twin of its traffic system. By analyzing real-time traffic data, the city can optimize traffic flow, reduce congestion, and improve emergency response times. This data-driven approach leads to a more efficient and livable urban environment. The impact on citizens’ daily lives, reducing stress and improving commute times, is a powerful testament to the technology’s potential.

The Future is Twin: Embracing the Potential

Digital twins are not just a technological advancement; they are a fundamental shift in how we design, build, and operate systems. They represent a move towards a more proactive, data-driven, and ultimately, more efficient world. The potential applications are vast and constantly expanding, promising a future where innovation is accelerated, risks are minimized, and efficiency is maximized.

But the journey is just beginning. We need to continue to develop the technologies that underpin digital twins, fostering collaboration between industry, academia, and government to unlock their full potential. This requires a collective effort to address the challenges of data security, interoperability, and the development of standardized frameworks.

Call to Action:

Are you ready to embrace the silent revolution? We encourage you to explore the possibilities of digital twins within your own organization. Reach out to us to discuss how we can help you leverage the power of digital twins to transform your business. Let’s shape the future, together. Join the conversation – share your thoughts and experiences with digital twins in the comments below. Let’s learn from each other and build a better future, one digital twin at a time.

| Feature | Traditional Approach | Digital Twin Approach |

|---|---|---|

| Software Testing | Limited testing, potential for late-stage bugs | Comprehensive virtual testing, early bug detection |

| Maintenance | Reactive, scheduled maintenance | Predictive, proactive maintenance |

| Design & Eng. | Prototyping-heavy, costly iterations | Virtual prototyping, faster iteration, reduced costs |

| Optimization | Manual adjustments, limited insights | Data-driven optimization, real-time insights |

| Risk Management | Reactive response to issues | Proactive risk identification and mitigation |

This table summarizes the key differences between traditional approaches and those enabled by digital twins, highlighting the significant improvements in efficiency, cost-effectiveness, and risk management.